Role of Hydraulic Presses for Microelectronics Manufacturing

Microelectronics is at the heart of today’s rapidly evolving industries.

From telecommunications and automotive to consumer electronics, the demand for microelectronics continues to grow exponentially.

Smartphones, electric vehicles, and advanced medical devices all rely on small yet powerful components that must be manufactured with absolute precision.

In this high-stakes environment, hydraulic presses play a crucial role in ensuring the consistency and quality of microelectronic components.

At Magnum Press, we lead in custom hydraulic press solutions designed to meet the exacting demands of microelectronics manufacturing. With decades of expertise, Magnum Press delivers precision, reliability, and innovative solutions for manufacturers looking to stay ahead in this competitive space.

Overview of Microelectronics Manufacturing

As the backbone of modern technology, microelectronics manufacturing plays a crucial role in driving innovation across various industries.

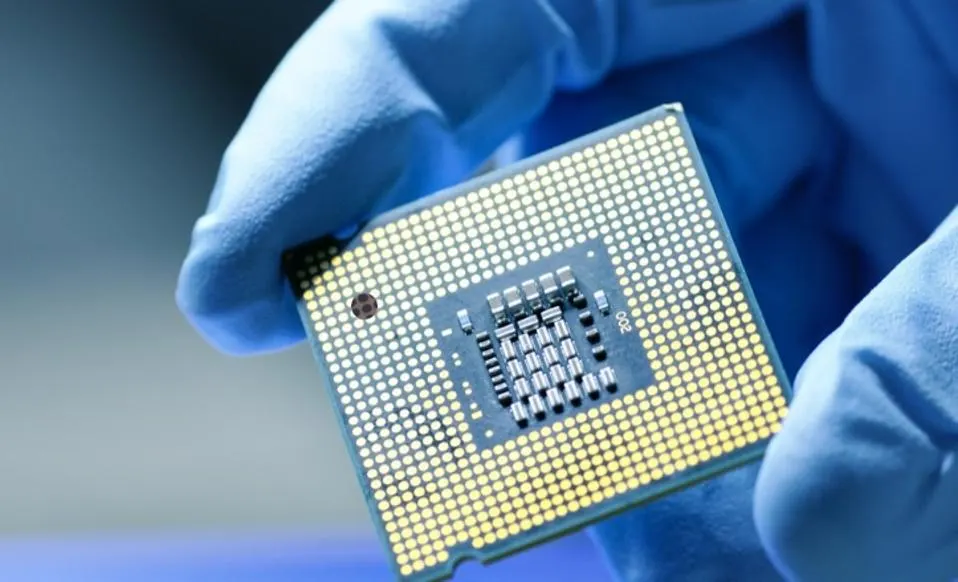

What Are Microelectronics?

Microelectronics refers to the production of small, intricate electronic components, such as semiconductors, integrated circuits, sensors, and connectors.

These components are vital for devices ranging from smartphones, to the automotive industry, and to aerospace systems.

Precision is everything in microelectronics, where even the slightest imperfection can result in faulty performance or total failure of a device.

The Importance of Precision in Manufacturing

Microelectronics components demand extremely high precision during production.

The slightest variation in force or pressure during the manufacturing process can lead to defects, reducing the functionality of the final product.

Whether it’s forming microchips, laminating circuit boards, or assembling sensors, accuracy is crucial at every stage.

Role of Hydraulic Presses

Hydraulic presses offer controlled force and pressure—two essential elements in microelectronics manufacturing.

These presses are responsible for applying precise amounts of pressure during critical production steps like bonding, compacting, and encapsulating.

The ability to fine-tune these processes ensures consistency, reliability, and the high-quality standards required in microelectronics.

Why Magnum Press Hydraulic Presses are Perfect for Microelectronics

In the fast-paced world of microelectronics, precision and reliability are vital, making the right press essential for success.

Precision Engineering for Small Components

Magnum Press excels in delivering hydraulic presses that cater to the requirements of microelectronics. These machines offer unmatched precision, ensuring every press operation maintains the integrity of delicate components. Whether it’s stamping, laminating, or assembling, our hydraulic presses provide consistent force, allowing manufacturers to achieve perfect results.

Custom Solutions for High-Volume Production

We design custom hydraulic presses tailored to the specific needs of microelectronics manufacturers. High-volume production is essential in this field, and we excels in delivering press systems that optimize efficiency without compromising quality. Every press can be adjusted to fit the exacting standards of microelectronics, ensuring flawless performance on a mass scale.

Versatility to Accommodate Diverse Applications

No two microelectronics projects are the same, and we understand this. They offer versatile hydraulic press solutions that are adaptable to various microelectronics tasks. Whether it’s compacting powders to form microchips or assembling tiny connectors, we deliver custom solutions that meet the diverse needs of microelectronics manufacturers.

Key Benefits of Using Magnum Press Hydraulic Presses in Microelectronics Manufacturing

In the competitive world of microelectronics, choosing the right equipment can significantly impact production efficiency and product quality.

Precision and Accuracy for Delicate Components

Our hydraulic presses provide unparalleled precision, handling delicate electronic parts without damage. With fine control over pressure and movement, manufacturers can create components that meet the stringent demands of the microelectronics industry.

Consistent Quality and Reliability

Uniformity in pressure application is key to ensuring every component produced is of the highest quality. Our hydraulic presses offer consistent force, which translates to reliable and repeatable results—an essential requirement in the microelectronics sector.

Efficiency and High Throughput

In a field where demand continues to grow, we designs our hydraulic presses for high-volume production. These machines are built to handle the pressures of mass manufacturing while maintaining top-notch efficiency, allowing manufacturers to meet increasing market demands with ease.

Flexibility for Different Applications

Our hydraulic presses are customizable and versatile, accommodating a wide range of microelectronics manufacturing processes. Whether compacting, laminating, or assembling, we can tailor our machines to the specific needs of each project.

Durability and Cost Efficiency

Built to last, our hydraulic presses are engineered for long-term performance. This durability translates to significant cost savings for manufacturers, as their machines require less maintenance and deliver consistent results over time.

Applications of Magnum Press Hydraulic Presses in Microelectronics

Our hydraulic presses are designed to meet the specialized demands of microelectronics manufacturing, providing solutions for a variety of applications.

Bonding and Laminating

Hydraulic presses are essential in bonding and laminating various layers within microelectronics components. Our machines ensure strong, reliable connections that enhance the overall integrity and functionality of these products.

Encapsulation and Sealing

Our hydraulic presses play a critical role in encapsulating microelectronic components, protecting them from environmental factors like moisture, dust, and contaminants that could compromise their performance.

Precision Stamping and Compacting

Precision stamping and compacting are essential for creating intricate patterns and shapes in microelectronics. Our hydraulic presses offer the perfect balance of force and control, enabling the production of complex designs with flawless accuracy.

Assembly of Sensors and Connectors

In the assembly of sensors and connectors, precision is key. Our hydraulic presses provide the controlled pressure necessary to assemble these critical components without damaging them, ensuring optimal functionality.

Advanced Features of Magnum Press Hydraulic Presses for Microelectronics Manufacturing

Our hydraulic presses are equipped with cutting-edge features specifically designed to enhance efficiency and precision in microelectronics manufacturing.

Smart Control Systems for Precision

We integrates smart control systems into our hydraulic presses, allowing manufacturers to make fine-tuned adjustments to pressure and movement. This ensures maximum precision during the production of microelectronics components.

Automation and Integration

Automation is a growing trend in microelectronics manufacturing. Our hydraulic presses offer automated features that reduce manual intervention, streamlining production and increasing overall efficiency.

Safety Measures for Delicate Operations

We prioritizes safety in our hydraulic press designs. Built-in safety features protect both operators and the delicate microelectronic components they are working with, ensuring smooth, incident-free production.

Future Trends in Hydraulic Presses for Microelectronics Manufacturing

As the industry evolves, so do the technologies that support it, ensuring manufacturers remain competitive and efficient.

Miniaturization and Precision Technology

As electronics continue to shrink in size, the demand for precision in manufacturing increases. We are at the forefront of this trend, providing hydraulic presses equipped to handle increasingly smaller and more intricate components.

Digital Integration and Smart Presses

We leads the way in integrating digital technologies into hydraulic presses. Features like remote monitoring, predictive maintenance, and data-driven optimization are setting the stage for the next generation of microelectronics manufacturing.

Sustainability and Efficiency

Sustainability is a top priority for modern manufacturers, and we are committed to developing energy-efficient hydraulic presses. These machines help reduce the environmental impact of microelectronics manufacturing while maintaining the highest levels of productivity.

Contact Magnum Press Today!

We deliver unmatched precision, efficiency, and reliability in the microelectronics manufacturing space.

With tailored hydraulic press solutions designed for the specific needs of this industry, we help manufacturers produce high-quality components that meet the growing demands of today’s tech-driven world.

Ready to optimize your microelectronics production? Reach out to us and discover how our cutting-edge hydraulic presses can elevate your manufacturing processes!