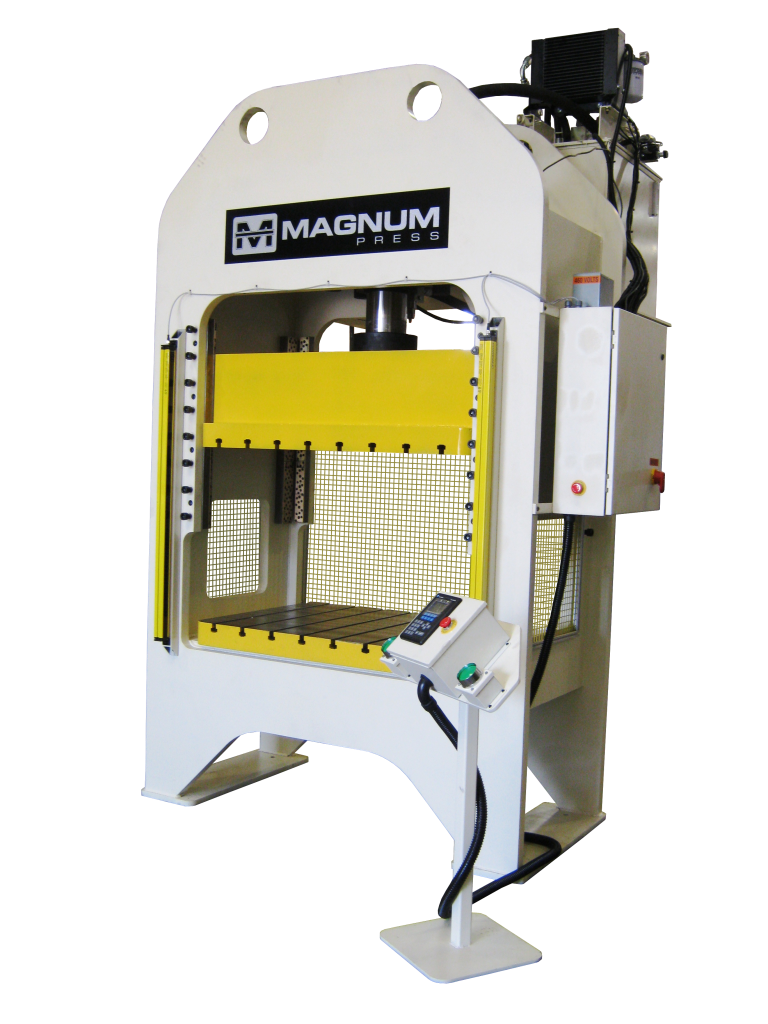

Straight Side Press Series

Straight-side presses are an important piece of equipment in several industries for their robust design and high-tonnage capacity.

These features allow them to excel in high-precision applications, including stamping, deep drawing, and assembly. And, with its stable structure and high-tonnage capacity, straight-side hydraulic presses can handle a wide range of materials, like aluminum and high-strength alloys.

Their exceptional rigidity, superior load distribution, and consistent performance make them ideal for heavy-duty applications that require efficient and precise production.

What is a Straight Side Press?

A straight-side press is a robust press design that can utilize sturdy slab steel sides or columns on each side. These slabs or columns provide the stability and rigidity required for various forming operations. And, unlike C-frame / gap frame press design, frame deflection is minimized making it suitable for high-tonnage and high-precision applications. Straight side presses typically utilize GIB guided platens providing resistance to moderate off-center loading.

Key Features of a Straight-Side Press

Stable Structure

A stable structure is one of the defining characteristics of a straight-side press. This is thanks to the frame that encloses the entire machine.

High-Tonnage Capacity

Due to their design, straight-side presses have a higher tonnage capacity compared to other types of similar size. This allows for complex and demanding operations, like deep drawing and heavy stamping, while maintaining the required precision.

Large bed area

The bed, or bolster, of a press is where the lower part of the die is clamped or bolted. Its construction allows for a large bed area, providing more flexibility for accommodating a variety of die designs

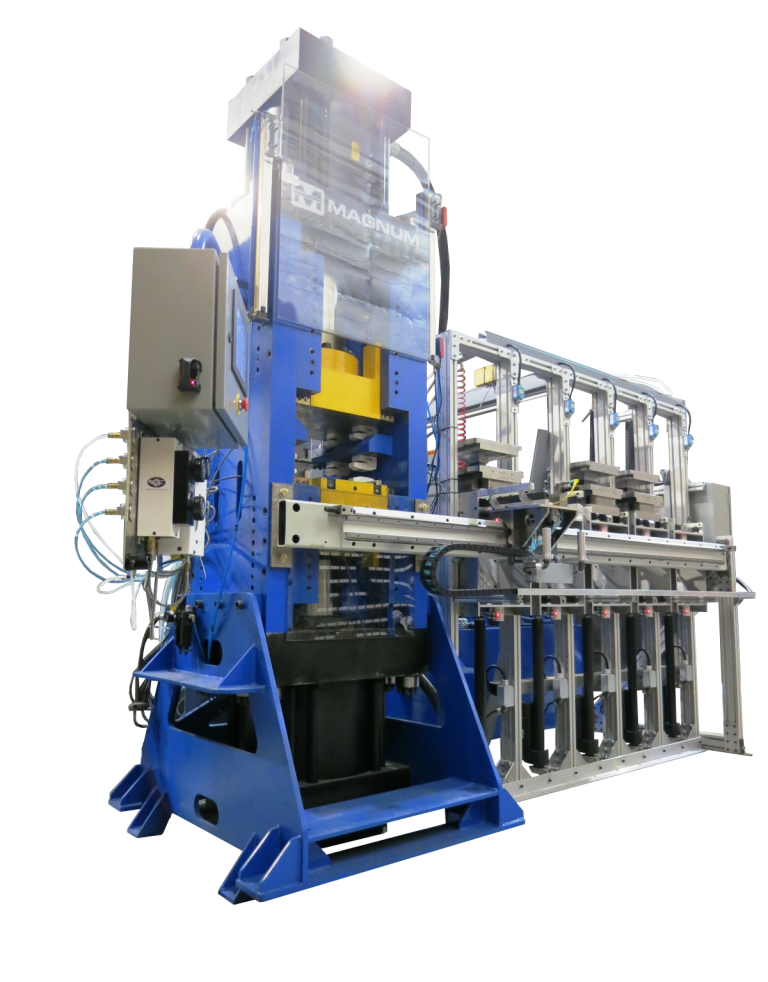

Automation compatibility

Straight-side presses can be integrated with feed systems, transfer mechanisms, and other automation systems.

Applications of Straight Side Presses

Straight-side presses are versatile machines used in various industrial and manufacturing processes. Their robust design and high-tonnage capacity make them ideal for a wide range of applications. Here’s how different sectors utilize straight-side presses for their use:

Metal Stamping and Forming

Straight-side presses are the backbone of metal stamping processes. They can consistently create parts with precision through various stamping operations like blanking, punching, bending, and coining. Their relative high-tonnage capacity makes them suitable for forming both light and heavy gauge metal materials into components.

Deep Drawing Operations

Deep drawing is a metal-forming process that involves a sheet metal blank being radially drawn into a forming die with the mechanical action of a punch delivered by a hydraulic press. With its capability to apply the necessary force evenly, using a straight-side press for deep drawing allows for consistent production of pieces free from wrinkles and tears.

Large-Scale Assembly Processes

Straight-side presses can provide the required precision and power for joining components in a large-scale assembly operation. It can be used for riveting, crimping, and press-fit assembly. And, with its large bed area and stable structure, it can be used for the assembly of large pieces while making it easy to ensure all parts are aligned properly.

Automotive and Aerospace Component Manufacturing

The automotive and aerospace industries require parts that meet strict standards for strength and precision. Straight-side presses can manufacture parts that meet these standards with their stable frame and even force application. And their high-tonnage capacity allows them to form the high-strength materials used in these industries.

Advantages of Using Straight Side Presses

Straight-side presses are a staple in the manufacturing industry for their robust construction and versatility. They offer numerous advantages that make them a preferred choice for high-precision and heavy-duty applications. Here are the benefits that straight-side presses have to offer:

High Rigidity and Stability for Precise Operations

A straight-side press features a solid frame with vertical columns on either side. This provides exceptional rigidity and stability in its operations, allowing it to produce consistent and accurate products in high volumes. This makes it essential for any operation that requires precise results.

Superior Load Distribution for Heavy-Duty tasks

Straight-side presses have a symmetrical design. This ensures even load distribution across the bed, which is critical for the efficient production of components without any wrinkles or tears. And this even load distribution reduces the risk of off-center loading, which can lead to premature wear or damage to the equipment.

Consistent Performance for High-Volume Production

High-volume production requires the delivery of products that pass the standards with little to no error over an extended period of time. A straight-side press can deliver this performance due to its stable structure and high-tonnage capacity. And, with its reliability, it can meet production demands while keeping operational costs and interruptions in check.

Versatility in Applications and Material Handling

Straight-side presses can handle a wide range of materials, from soft aluminum to high-strength alloys. These make them suitable for a wide range of applications across different sectors, including automotive body panels, aerospace components, and electronic enclosures. The advantages mentioned above make straight-side presses an invaluable asset in any manufacturing setting where precision, efficiency, and versatility are necessities.

Why Choose Magnum Press for Straight Side Presses

Expertise and Industry Leadership

With our decades of experience, we can deliver hydraulic presses that provide the solution for your exact manufacturing requirements. Our in-house team of engineers has the knowledge and experience to deliver custom, top-tier solutions for your needs.

Robust Construction and Reliable Performance

We build heavy-duty hydraulic presses designed for long-lasting performance and easy maintenance and repair, ensuring you meet production requirements efficiently with little to no interruptions.

Versatility and Adaptability

Magnum Press designed its presses for versatility, allowing one press to be used for a wide range of applications. And, with easy adjustments, you can make the necessary changes quickly to ensure optimal production in your line.

Customization Options Tailored to Your Specific Needs

We build heavy-duty hydraulic presses designed for long-lasting performance and easy maintenance and repair, ensuring you meet production requirements efficiently with little to no interruptions.

Exceptional Customer Service and Support

Magnum Press provides several resources and a variety of services to ensure your team can operate your hydraulic presses safely and efficiently. We also offer periodic maintenance and repair services to keep your equipment in top shape for optimal production.

Contact Us Today to Learn More About Magnum Press’ Straight-Side Presses

Ready to enhance your production with a high-performance and efficient straight-side press? Contact us for more information or to request a quote for our hydraulic presses. We are here to help you find the perfect solution for your requirements. Click the button below to contact our team!