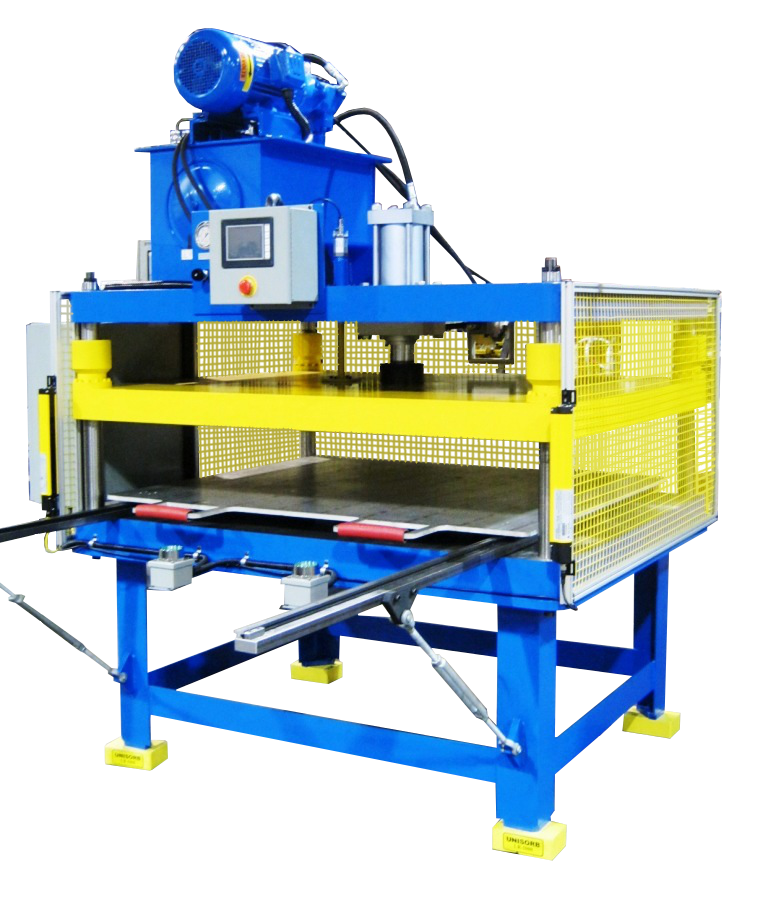

Steel Rule Die Press Application

Steel rule die cutting presses are essential tools for cutting and shaping a variety of materials with precision and efficiency.

Its ability to cut materials into specific shapes in high volume made it an essential machine across industries such as packaging, textiles, automotive, and electronics. And, with its cost-effectiveness, efficiency, and durability, this hydraulic press can help any manufacturer maximize their productivity while keeping their per-unit cost of production down.

What is a Steel Rule Die Cutting Press?

A steel rule die press is a die-cutting machine used for manipulating stock material by pressing a sharp steel rule down into it against a flat surface. This is done to turn soft and semi-rigid stock material into a specific shape or pattern. Stock materials manipulated in steel rule die-cutting include foam, rubber, cardboard, fiberglass, metal foil, plastics, paper, fabrics, and cork.

Steel rule die presses can perform various cutting operations, such as through cutting, kiss cutting, perforating, and creasing and scoring.

Applications of Steel Rule Die Presses

Steel rule die cutting presses are prominently used in the manufacturing operations of the packaging, textile, automotive, and electronics industries. Here’s how each industry makes use of hydraulic steel rule die presses:

Packaging Industry

The packaging industry uses steel rule die presses for cutting various packaging materials into shapes tailored to specific products. With the cost-effectiveness of these presses, they are an inexpensive option for creating bulk packaging for a wide range of design requirements with different materials, including cardboard, corrugated fiberboard, and plastics.

Textile Industry

Textile manufacturers cut multiple layers of fabrics, leather, and other materials with steel rule die presses to produce consistent and high-quality products in high volumes. The versatility of steel rule die presses allows them to cut a variety of patterns, including intricate designs for home textiles and accessories.

Automotive Industry

Steel rule die presses are used in the automotive industry for the production of high-precision parts. Various materials, such as metals, plastics, and composites, are cut into the specified shapes for producing gaskets, seals, and interior trim pieces.

Electronics

The electronics industry uses steel rule die presses for producing small components like circuit boards, connectors, housings, and rigid enclosures. This is due to the precision that these presses have in cutting various materials, including thin and flexible ones, into the specified shape and dimensions.

Advantages of Using Steel Rule Die Presses

Steel rule die presses offer numerous advantages that make them indispensable tools in various industries. They can produce high-quality products in a cost-effective manner and in high volumes. And, with their versatility in handling wide ranges of materials and producing different shapes, manufacturers can use a single machine for multiple applications.

Precision and Accuracy

The sharp steel blade, bent into the desired shape, of a steel rule die cutting press ensures the cuts it makes are consistent and exact. This allows you to achieve detailed and intricate cuts that meet the stringent specifications of your final product.

Cost-Effectiveness

The initial investment required for a steel rule die press is relatively low compared to other cutting equipment for large production runs. Using it allows for a reduced per-unit cost of production for your manufacturing operations. And, with its durability and longevity, it further contributes to the cost and production efficiency of your operations, as they require less maintenance or repairs.

Versatility in Materials and Shapes

Steel rule die presses can handle a wide range of materials and shapes. They can cut through cardboard, plastics, textiles, metals, and more and produce complex and intricate shapes for creating custom designs. This allows manufacturers to use the same equipment for different applications, reducing the need for multiple machines.

Efficiency in High-Volume Production

Steel rule die presses are capable of making multiple cuts in a single operation, making them highly efficient in high-volume production scenarios. This efficiency is crucial in manufacturing operations with high demand and tight deadlines.

Why Choose Magnum Press for Steel Rule Die Presses

Unmatched Industry Expertise

With more than two decades in the industry, Magnum Press has developed a deep understanding of the needs and challenges faced by various industries. We use this extensive knowledge to design and build hydraulic presses that meet the highest standards of precision, reliability, and efficiency.

High-Quality Materials and Construction

We only use the finest materials and parts and state-of-the-art construction techniques to build our steel rule die presses and hydraulic presses. Each press is engineered to provide exceptional durability, long-term reliability, and easy maintenance and repairability.

Customization Options

Magnum Press understands that every business has unique needs. This is why we offer customization options for our hydraulic presses, tailoring them to meet your exact requirements. We can even design and build you a steel rule die press from scratch if any of our presses do not meet your specifications.

Exceptional Customer Service and Support

From initial consultation to ongoing maintenance and support, we provide exceptional service to our clients to ensure optimal performance from your hydraulic press. And we can also provide training and the necessary resources to help ensure your team can operate your machines safely and efficiently.

Contact Us for More Information

Ready to take your production capabilities to the next level with Magnum Press’ steel rule die cutting presses? Contact us today to learn more about the presses we offer or for a personalized quote for the solution you require. Our team is here, ready to help and answer your inquiries and questions!