Hydraulic Presses For The Automotive Industry

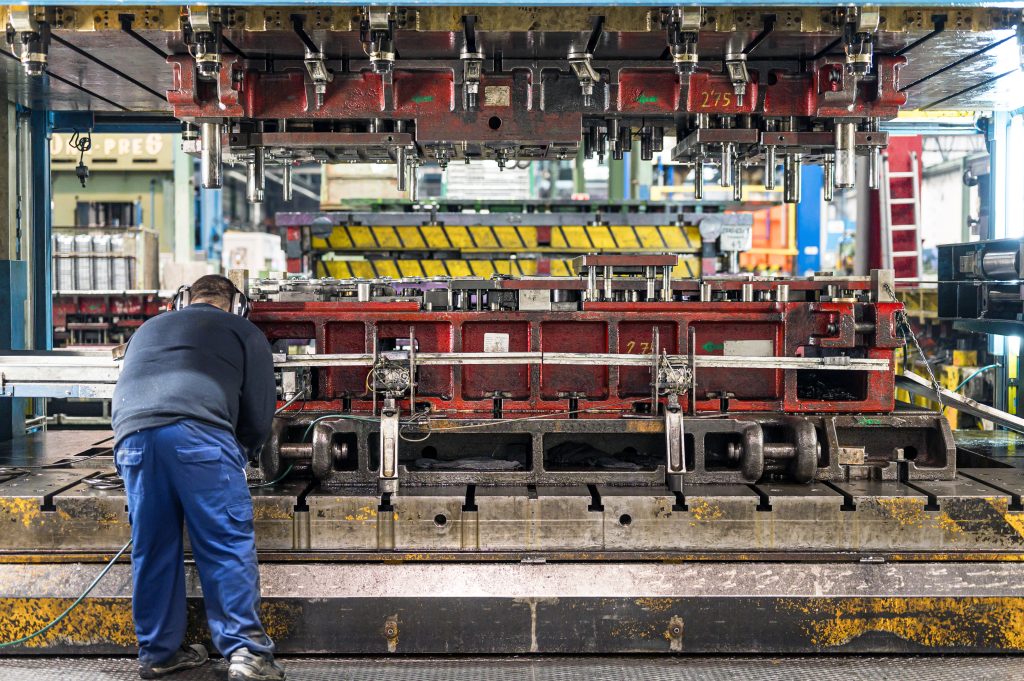

Hydraulic presses play an essential role in the automotive industry, offering precise forming, stamping, and assembly of automotive components.

Magnum Press is a leading hydraulic press manufacturer that provides a wide range of hydraulic press machines specifically designed for automotive production lines.

With innovative solutions prioritizing precision, efficiency, and operator safety, Magnum Press stands out as the ideal solution for automotive manufacturers seeking to optimize production processes.

The Role of Hydraulic Presses in Automotive Manufacturing

Hydraulic presses are vital in streamlining production processes and enhancing efficiency across various automotive applications.

Hydraulic presses are integral to automotive production, handling tasks like forming metal sheets, compression molding, and stamping.

These presses are essential for creating components such as body panels, frames, and other critical automotive parts with high precision and minimal material waste.

Hydraulic systems, including C-frame presses and straight-side presses, deliver consistent fluid pressure, ensuring that each part meets exacting specifications and contributes to the overall quality of finished products.

Magnum Press’s hydraulic presses offer several benefits, including precise control over pressure and cycle time, which is crucial for maintaining consistent production quality.

Our energy-saving hydraulic systems reduce energy consumption, offering a more sustainable approach to manufacturing.

Additionally, integrating features like light curtains and safety gates enhances operator safety, making these presses suitable for demanding industrial applications in the automotive sector.

Key Features of Magnum Press’s Hydraulic Presses for Automotive Manufacturing

Our presses are engineered to meet the specific demands of modern automotive manufacturing.

Magnum Press’s hydraulic presses provide precise control over the production process, allowing for the accurate formation of metal sheets and composite materials.

This precision is vital for producing automotive components that meet strict industry standards, giving manufacturers a competitive edge in a highly competitive industry.

Magnum Press’s hydraulic presses offer high tonnage capacity and are designed to handle the rigorous demands of automotive manufacturing.

These presses are equipped to manage the stress and strain of large-scale automotive production, whether it’s forming deep draws or handling heavy-duty stamping tasks.

Magnum Press’s hydraulic presses can be seamlessly integrated into automated production lines, enhancing overall production efficiency and consistency.

Integrating advanced hydraulic systems, cylinders, and pumps allows for optimized motor speed and fluid pressure, reducing cycle times and increasing throughput.

Benefits of Choosing Magnum Press for Automotive Manufacturing

Our dedication to innovation and quality ensures we meet the evolving needs of the automotive industry.

Hydraulic presses from Magnum Press contribute to producing high-quality automotive components by providing precise forming and consistent pressure control.

This ensures that each part is made with minimal defects, resulting in finished products that meet or exceed industry standards.

Magnum Press’s hydraulic presses are designed with energy efficiency in mind, helping automotive manufacturers reduce energy consumption and operational costs.

The advanced hydraulic press designs also support faster cycle times, allowing for increased production rates and meeting tight manufacturing deadlines.

Magnum Press’s hydraulic presses can handle various materials, from traditional metals to modern composites.

This versatility makes them ideal for producing a comprehensive range of automotive components, including those made from lightweight composite materials increasingly used in modern vehicles.

Built with rigid designs, Magnum Press’s hydraulic presses are engineered for long-term durability and reliability.

These presses can withstand the harsh conditions of automotive production environments, providing consistent performance over time and reducing the need for frequent maintenance.

Applications Across the Automotive Industry

Our hydraulic presses are designed to address the diverse needs of the automotive manufacturing process.

Body Panel Forming

Hydraulic presses are essential for forming vehicle body panels, such as doors, hoods, and fenders.

Magnum Press’s solutions ensure precise forming and uniformity, which are critical for automotive body components' aesthetic and structural integrity.

Chassis and Structural Component Manufacturing

Magnum Press’s hydraulic presses are ideal for manufacturing chassis and other structural components that require high strength and precision.

These presses handle heavy loads and provide the accuracy needed to produce parts like frames and suspension components.

Automotive Stamping

Stamping operations are a cornerstone of automotive manufacturing, used to create intricate parts from metal sheets.

Magnum Press’s hydraulic presses offer the precise control necessary for stamping, ensuring each part meets the specifications with minimal material waste.

Interior and Exterior Trim Production

Magnum Press’s hydraulic presses also form and assemble interior and exterior trim components, such as dashboards, consoles, and bumpers.

These presses provide the flexibility needed to produce a wide variety of trim parts, contributing to the overall quality and aesthetics of the vehicle.

Customization and Support from Magnum Press

We are committed to delivering innovative solutions that enhance manufacturing efficiency.

Tailored Solutions for Automotive Needs

Magnum Press specializes in providing customized hydraulic press solutions for the automotive industry.

Our team works closely with automotive manufacturers to design presses that meet specific production requirements, whether adjusting press tonnage, integrating advanced safety systems, or customizing press configurations.

Expert Consultation

Magnum Press offers expert consultation services to help automotive manufacturers select the best hydraulic press configurations for their applications.

This personalized support ensures that each press is tailored to the manufacturer’s production processes, enhancing overall efficiency and performance.

Comprehensive Support and Service

Magnum Press provides comprehensive support and maintenance services for our hydraulic presses to ensure optimal performance.

This includes routine maintenance, troubleshooting, and parts replacement, helping manufacturers maintain high productivity levels and minimize downtime.

Why Magnum Press is the Top Choice for Automotive Manufacturing

Our relentless pursuit of excellence sets us apart in the automotive sector.

Magnum Press has extensive experience in the automotive manufacturing industry, offering hydraulic press solutions that meet the specific needs of automotive manufacturers.

Our expertise and dedication to innovation make them a trusted partner for companies looking to enhance our production capabilities.

Magnum Press has a proven track record of success, demonstrated through numerous case studies and testimonials from satisfied automotive clients.

Our presses have consistently delivered the performance, reliability, and efficiency needed to excel in the automotive industry.

Magnum Press is committed to continuous innovation and maintaining the highest quality standards.

Our focus on developing advanced hydraulic press technologies ensures that automotive manufacturers receive cutting-edge solutions that drive our production forward.

Drive Your Automotive Manufacturing Forward with Magnum Press

Elevate your automotive manufacturing with Magnum Press’s hydraulic press solutions. Contact us today for more information, to request a quote, or to schedule a consultation.

Discover how our hydraulic presses can provide the precision, efficiency, and reliability your production lines need to stay competitive in the automotive industry. Reach out via our contact form or give us a call to get started!