Hydraulic vs. Mechanical Press: Which Suits Your Operation?

Choosing the right press for your operation is an important decision that affects the productivity, product quality, and overall operational costs of your business. Out of the various options available, the choice often comes down to either a hydraulic press or a mechanical press.

Each has its own unique benefits and applications, and which one is the best depends completely on your operations and objectives. In this article, you will learn the basics of hydraulic and mechanical presses, their specific applications across industries, and how to determine which ones best suit your operational requirements.

Learn About Your Options: Hydraulic Press vs. Mechanical Press

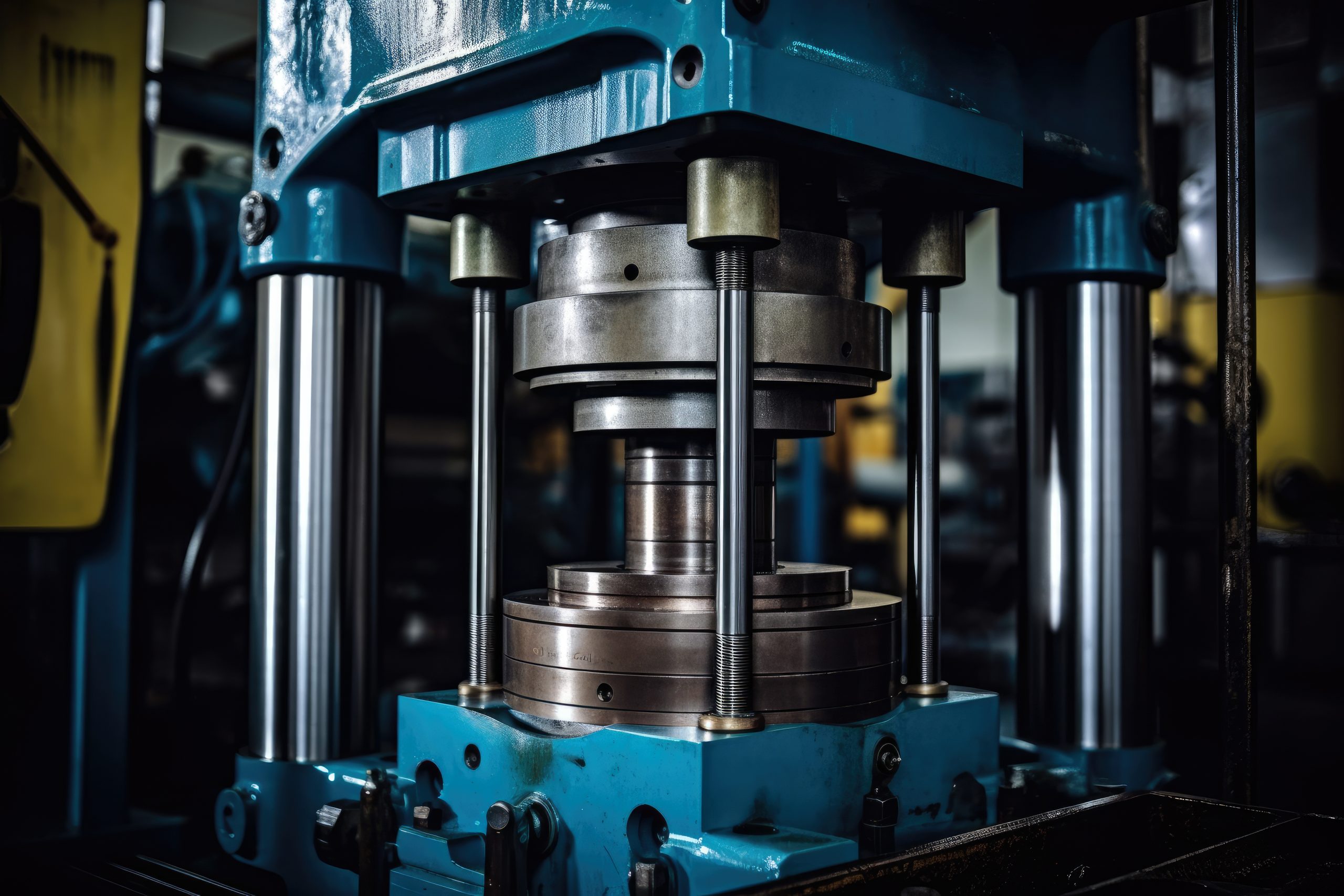

How Hydraulic Presses Work

How Mechanical Presses Work

Key Differences in Performance and Application

Understanding the distinct capabilities of hydraulic and mechanical presses is essential for selecting the right equipment for your needs.

Hydraulic Press

Excels in Heavy-Duty Applications

Hydraulic presses excel in heavy-duty applications for their ability to deliver a consistent pressure throughout the entire press stroke, making them ideal for tasks like deep drawing, molding, and forming complex, thick, or multi-material components.

Applications Requiring Precision

The speed and pressure of hydraulic presses can be fine-tuned for specific production requirements. And, unlike mechanical presses, their pressure can be set to vary in certain parts of the stroke, making them useful for manipulating components with varying thicknesses or sensitive compositions.

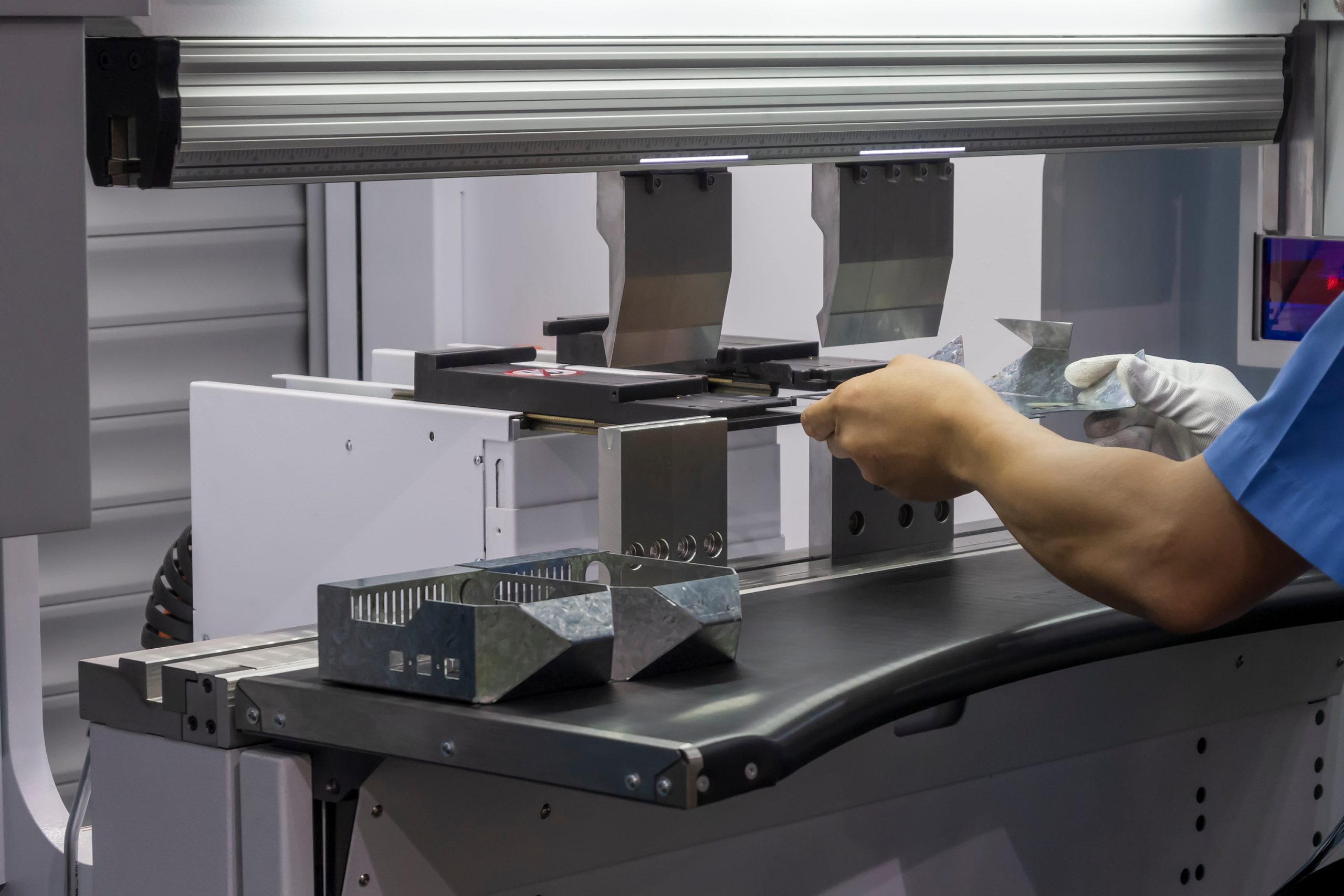

Production Lines that Require Versatility

Hydraulic presses can handle multiple die and tooling setups and provide different levels of pressure, making them adaptable for operations with changing production requirements or limited floor space.

Mechanical Press

Excels in High-Speed Production

Mechanical presses are perfect for high-volume production runs, such as metal stamping and punching, where quick turnaround times and precise results are critical.

Operations That Require Lower Maintenance and Increased Reliability

The simpler design of mechanical presses has fewer maintenance needs, making them ideal for operations that use their equipment for longer periods and where uptime is crucial.

Simple Industrial Applications

If you only have repetitive and straightforward tasks and operations, a mechanical press may be a better option for your business, given its lower cost. And, they are easier and more affordable to maintain, so you can save on maintenance costs over time.

Considerations for Choosing a Press

When choosing between a hydraulic or mechanical press, it’s important to consider various factors that will affect your production process.

Below are the key aspects to evaluate so you can ensure you choose the right press for your operation:

Tonnage and Force Requirements

Assess how much force you need based on the materials and tasks involved. And, determine whether you require the benefits that hydraulic presses deliver, such as uniform force throughout the whole stroke, variable tonnage delivered, or varying pressure through a stroke.

Type of Application

The type of work you will have the equipment to do plays a significant role in your press selection. For intricate tasks like deep drawing, molding, or forming complex shapes, hydraulic presses have better control and adaptability. On the other hand, mechanical presses are perfect for simpler applications that require speed and consistency, such as stamping and punching.

Production Speed

If production speed is a top priority, a mechanical press is typically the better option. It operates at high speeds and is suited for high-volume production with minimal setup time. To illustrate, they can perform up to 1,000 cycles per minute, which is a far cry from the average of 30 cycles per minute that hydraulic presses can perform.

Flexibility and Customization

Hydraulic presses offer unmatched flexibility in application. A single press can adapt different dies, tooling setups, and pressure and stroke settings, with the design being the only limiting factor to these customizations. Because of this, hydraulic presses are the go-to choice for businesses that require equipment to perform a variety of tasks or an operation producing different products.

Space and Size

Hydraulic presses generally require more space due to their complex systems. On the other hand, mechanical presses are more compact and can fit into smaller spaces. Make sure to evaluate the available floor space when choosing a press.

Energy Efficiency

Mechanical presses consume energy consistently during operation but are more efficient for continuous tasks. On the other hand, hydraulic presses vary in energy consumption, with them being more efficient in the long term but more power-hungry during extended, heavy-duty operations.

Maintenance and Downtime

Hydraulic presses have fewer moving parts, resulting in lower long-term maintenance costs long-term. But, they require regular checks to ensure optimal hydraulic fluid levels and system performance, which may add to your personnel, service, or training expenses. On the other hand, mechanical presses, with their higher number of moving components, may have more frequent breakdowns and require more maintenance.

Safety Features

Both mechanical and hydraulic presses come with built-in safety features. Hydraulic presses offer an advantage in this area with their precise control over the force applied, reducing the risk of overloading or causing damage to material or tools. Mechanical presses require more manual oversight, which presents increased risks, especially if not operated carefully.

Automation and Control Options

For operations looking to integrate automation, hydraulic presses have more control options, allowing you to fine-tune processes like speed and pressure in real time and automatically. They are ideal for operations that require automation and adaptability. As for mechanical presses, they can still support automation in high-speed, repetitive tasks, but they do not offer the same level of precise control.

Cost and Total Investment

Mechanical presses tend to have lower initial costs but higher long-term costs from maintenance and potential downtime. On the other hand, hydraulic presses may have higher upfront costs but lower long-term expenses, and they have greater versatility, which allows a single press to be utilized for several applications.

Choose the Right Press for Your Operation

When it comes to choosing between a hydraulic press and a mechanical press, the right choice depends entirely on your specific operational needs.

If your production requires high-speed production with repetitive tasks, a mechanical press is likely a better fit. On the other hand, if your operation requires versatility, precision, and the ability to handle varied materials and tasks, a hydraulic press will provide the adaptability and control needed for complex applications.

Ultimately, whether you choose a hydraulic or mechanical press should reflect your business’ production goals, materials, and long-term requirements for flexibility, maintenance, and efficiency. Evaluate your operational needs carefully, and consider each press’ strengths to ensure you’re making the best investment for your operation.

Get a Quote Today!

Looking for precision, adaptability, and power in your production line? Magnum Press’ hydraulic presses might be the perfect solution for your operation. Contact us today to get a quote for our models or a fully customized one for your needs.