About Us

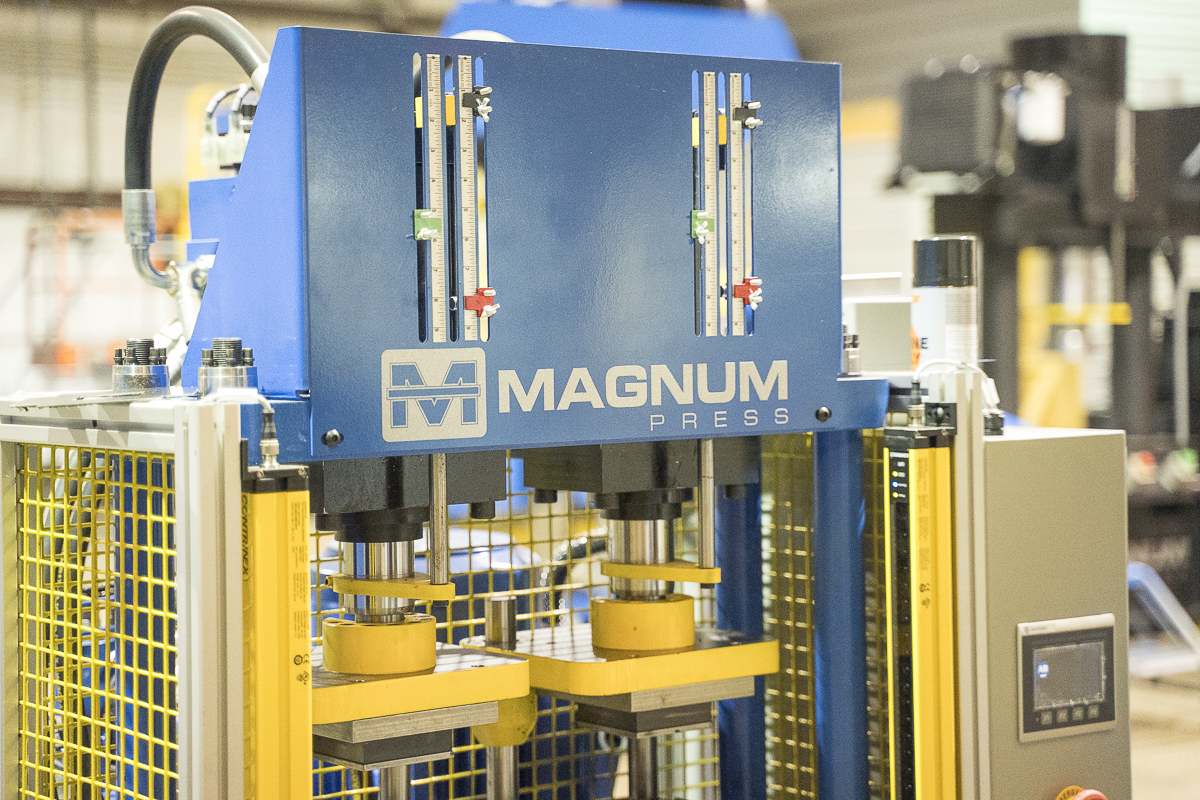

Magnum Press

Our Philosophy

HYDRAULICS

Magnum hydraulic systems are designed for presses. Our philosophy is to build simple, reliable, and easily serviceable systems. At the heart of our system are steel manifolds designed to consolidate valving, reduce pluming, eliminate leaks, and provide maximum service life. All pressure connection points have o-ring seals – no metal to metal pressure connections – no pipe threads. We use flexible wire braided hose to isolate frame stresses from reservoir and power units yet, maintain crisp system response. Our systems are designed with minimal pressure drops to allow lower usable tonnage range. All systems incorporate decompression on the blind side of the cylinder to eliminate shock pressure waves and ensure maximum service life for the system components. The entire system is designed to minimize response time to give you more parts per shift. Components are standard off the shelf, so replacements are readily available. Our manifolds incorporate efficient cartridge valve design that has extremely low leakage, fast shift time, and low pressure drops, all adding to system efficiency. Larger systems use piloted logic elements called poppet valves. These valves outperform large piloted spool valves in leakage, flow, and response time. Reservoirs are generously sized to minimize the need for external system cooling. Gap frame power units are self-contained and removable for service or remote location. Cylinders are premium quality NFPA compliant with easily serviceable rod bearings and seals.

ELECTRICAL

Our History

Magnum Press is a high-quality manufacturer of high-speed hydraulic press and automation equipment that is located in Adamsville, Tennessee. Magnum Press was founded in 1996 by second generation hydraulic press industry veteran, Pat DeStefano Jr, with just three employees while owner Phil Green came from a 25 year management and sales career with one of the highest quality fluid power distributors in the US. Magnum Press has continued to grow and offers a full range of standard and custom presses and continues to be in the business of making sure you get the right hydraulic press for the job. Magnum offers a full line of high speed standard gap frame press models in Standard C Frame configuration, 2-Post and 4-Post Guided Tool Plate, GIB Guided and Compact models. Custom 2-Post and 4-Post Column presses are quickly designed and manufactured to your custom specifications. With a standard hydraulic press variety from 2 to 300 ton and broad-reaching custom capabilities to 1500 ton and beyond, Magnum Press, Inc. has the hydraulic press for you.

Hydraulic Systems

Our Equipment