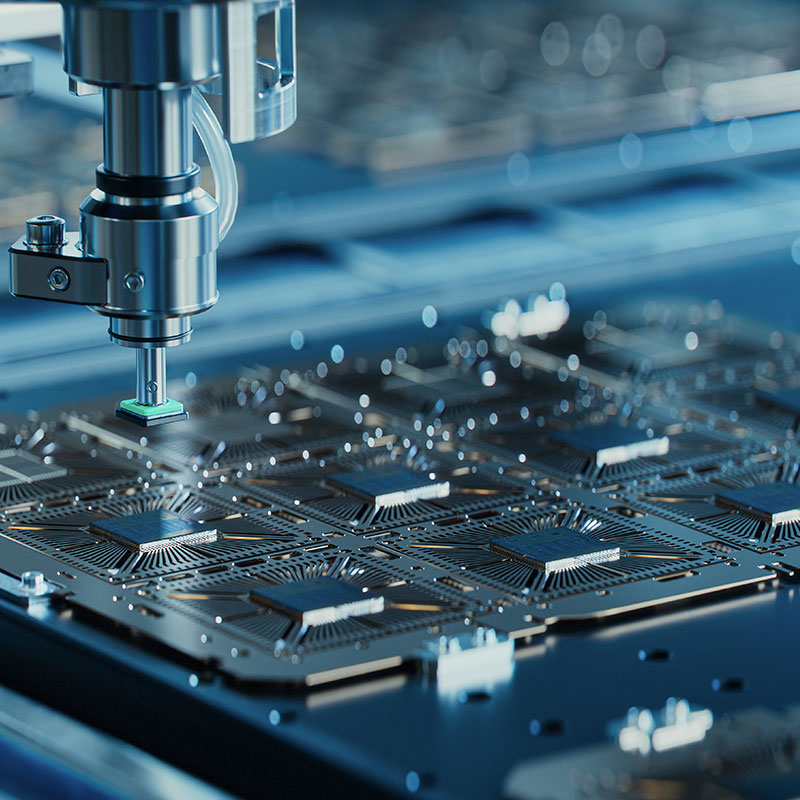

Staking Press

Make Metalworking Easy with Versatile Shop Presses

Precision and control

Adaptability to materials

Simple designs and off-the-shelf parts for easy repair

Customizable presses

Comprehensive technical support and services

Contact us today for a personalized quote for your staking press requirements.

Click the link below to get started.

Why Magnum Press

Magnum Press’ Hydraulic Presses for Staking

C-Frame Bench Presses

MCC

Tonnage Capacity: 2 to 35 tons

Features: Standard ram anti-rotation; Die coupler attach to tooling

MCB

Tonnage Capacity: 2 to 40 tons

Features: Standard ram anti-rotation; Die coupler attach to tooling; Available in standard and high-speed models

M2PB

Tonnage Capacity: 2 to 40 tons

Features: 2-post ram, 2-post upper platen tool plate, Centered load

M4PB

Tonnage Capacity: 2 to 40 tons

Features: GIB-guided, Off-center load, Available in standard and high-speed models

MGB

Tonnage Capacity: 10 to 40 tons

Features: GIB-guided, Off-center load, Available in standard and high-speed models

MCD

Tonnage Capacity: 2 to 40 tons

Features: Standard ram, Centered load

MSB

Tonnage Capacity: 2 to 40 tons

Features: Wide bolster plate, Lever valve operation, Available in standard and high-speed models

C-Frame Floor Model Presses

M2PF

Tonnage Capacity: 4 to 300 tons

Features: 2 post ram, 2 post upper platen tool plate, Center load

M4PF

Tonnage Capacity: 4 to 300 tons

Features: 4 post ram, 4 post upper platen tool plate, Center load

MCF

Tonnage Capacity: 4 to 300 tons

Features: Standard ram anti-rotation, Die coupler attach to tooling, Center load

Column Presses

M2P

Tonnage Capacity: 2 to 300 tons

Features: 2-post, Standard ram, Standard and high-speed models available

M2PS

Tonnage Capacity: 2 to 300 tons

Features: Precision guided platen, 2-post, Centered load

M4P

Tonnage Capacity: 10 to 250 tons

Features: Precision-guided platen, 4-post column, Center load

Straight Side Presses

Customization Options Are Available