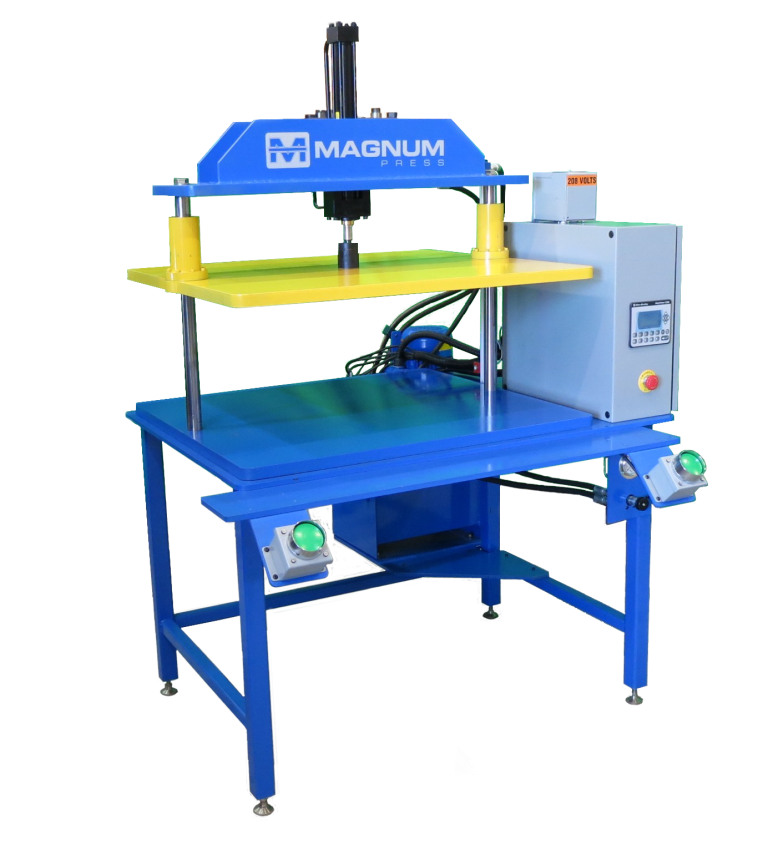

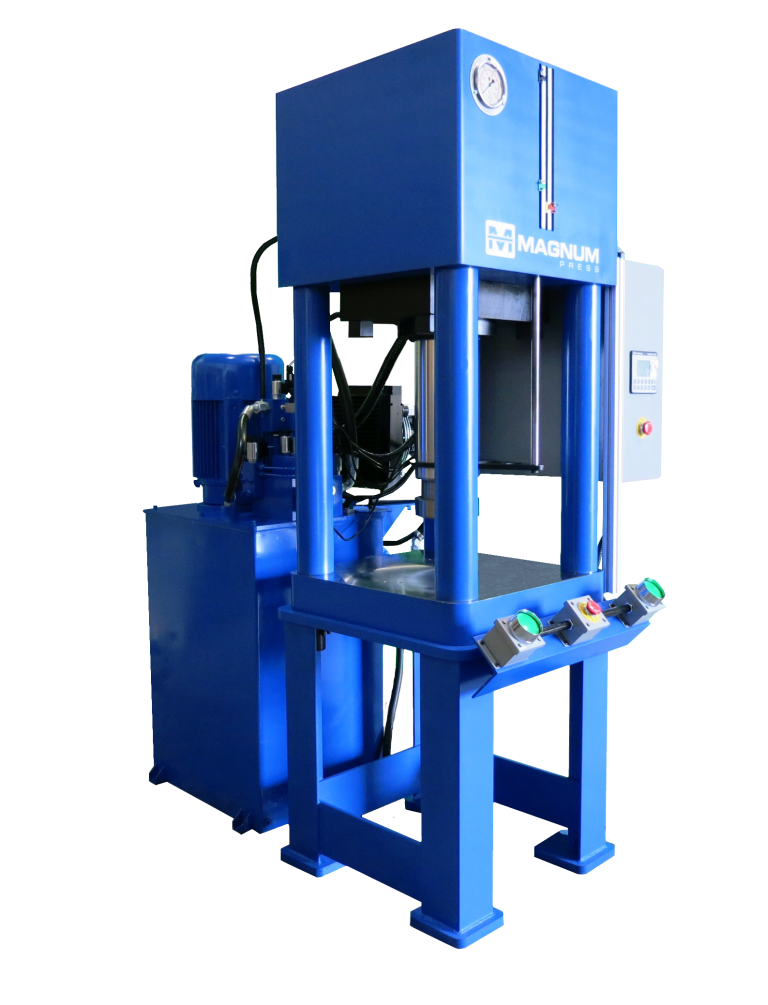

Column Press Series

Column presses are the best tools for your production line if you are looking for a hydraulic press that has high precision and stability with access on all sides of the work area for applications that have centered loads. It can be used for a wide variety of applications where superior parallelism between the bed and the platen are needed including metal forming, plastic molding, assembly, and component fabrication. And, with the integration of automation and monitoring features, a column press can be one of the most efficient and useful pieces of equipment on your production floor.

What is a Column Press?

A column press is a type of vertical or horizontal press that uses columns for frame construction. They can be built without or with a precision guided platen riding on the columns or posts. The posts are on the centerline of the left and right of the forming area for 2-post column presses, or on the corners for 4-post column presses. These columns guide the ram, ensuring uniform load distribution and minimal deflection during operation for centered-load applications. Column Presses offer superior parallelism between the bed and the slide platen when compared to gap frame presses.

Additionally, column presses offer unmatched access to their work area. Guarding can be added to all sides of the press.

Application of Column Presses

Column presses are vital tools in multiple manufacturing applications for their ability to exert controlled, consistent pressure and their robust design that can handle high-volume production. These applications include metal forming, plastic molding, assembly operations, and component fabrication.

Metal Forming

Column presses are essential tools for stamping, deep drawing, and forming metal materials into their specified forms. With its uniform load distribution and high tonnage capacity, it can be used for producing a wide variety of components while ensuring the production of pieces without wrinkles and tears.

Plastic Molding

Injection molding and compression molding are just two of the plastic molding applications that column presses can handle. Column hydraulic presses the mold to apply equal pressure all throughout and ensure it remains under pressure until the material solidifies according to specifications.

Assembly Operations

Like any hydraulic press, a column press can be used for assembly operations. Particularly, it excels at press-fitting heavy-duty or delicate components together. This is due to the columns these presses have that guide the ram and equalize the pressure on the components during operation.

Component Fabrication

Fabricating components often involves shaping and forming various materials into precise, functional parts that fit the specifications. Column presses are indispensable for these applications and in producing components that meet stringent standards for their enhanced load distribution, high precision and stability, and high-volume production capabilities.

Advantages of Using a Column Press

High Precision and Stability

Column presses have a rigid frame and guided moving components. This gives them high precision and stability in their operations, which are significant factors for producing components accurately and consistently in a production line.

Enhanced Load Distribution and Strength

A column press has a structural design that enhances its load distribution and strength, ensuring the applied force is evenly distributed across the working surface. This gives them the capability to produce workpieces with little to no risk of deformation or damage to the final product or the machine.

Versatility in Handling Tasks and Materials

Column presses are capable of handling a wide range of tasks and materials. These presses can be adapted for punching, bending, forming, assembly, riveting, blanking, brake pressing, coining, staking, and shop press applications. With interchangeable tooling and configurations, manufacturers can tailor the press for their specific production requirements.

Efficient Performance for High-Volume Production

Column presses can maintain consistent performance over extended periods, making them suitable for mass production runs. With automation features and integrated monitoring systems, its efficiency can be further enhanced while ensuring each product meets quality standards without extensive rework.

Why Choose Magnum Press for Column Presses

Choosing the right manufacturer for your column presses is crucial for ensuring the efficiency of your manufacturing process and the quality of your products. Magnum Presses is the leading provider in America for our unmatched expertise, superior construction, extensive customization options, and exceptional customer service and technical support.

Expertise and Industry Reputation

Magnum Press has decades of experience serving a wide range of industries with precision-engineered hydraulic presses for heavy-duty applications. Throughout the years, we have worked with several manufacturers to create high-performing and reliable presses that are designed to their exact specifications.

Superior Construction and Durability

We prioritize durability and robustness in every column press we design and manufacture. Our hydraulic presses are designed with high-grade materials and off-the-shelf parts to ensure long-term reliability and repairability.

Customization Options

Our hydraulic presses can be customized according to your specifications. And, if you have a more specific requirement, Magnum Press can design and build a hydraulic press from scratch to meet your requirements without any compromises.

Exceptional Customer Service and Technical Support

Our team here at Magnum Press is ready to assist you at every step, from initial consultation and installation to ongoing support and maintenance. With our training and technical resources, we can help ensure your team is equipped to safely and efficiently use your new hydraulic presses.

Enhance Your Production Capabilities with Magnum Press

Choose Magnum Press to partner with a company that combines extensive industry expertise and exceptional customer service and support. Contact us today to consult with our team and start improving your production capabilities with our column presses. Click the button below to contact us!